Insect Farm Hub

Global platform for insect farmers and businesses

Are you looking to become a professional insect farmer or start a business turning waste into valuable products with Black Soldier Fly?

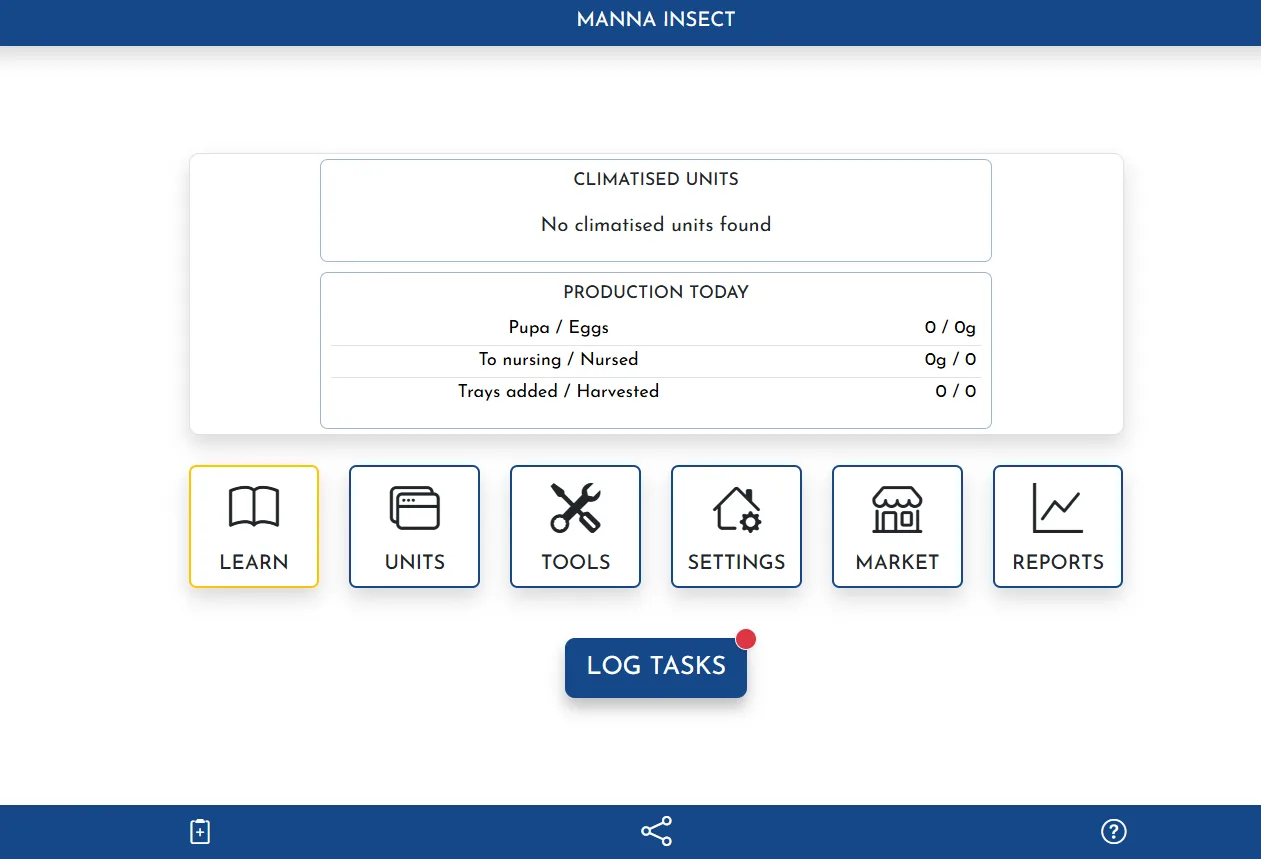

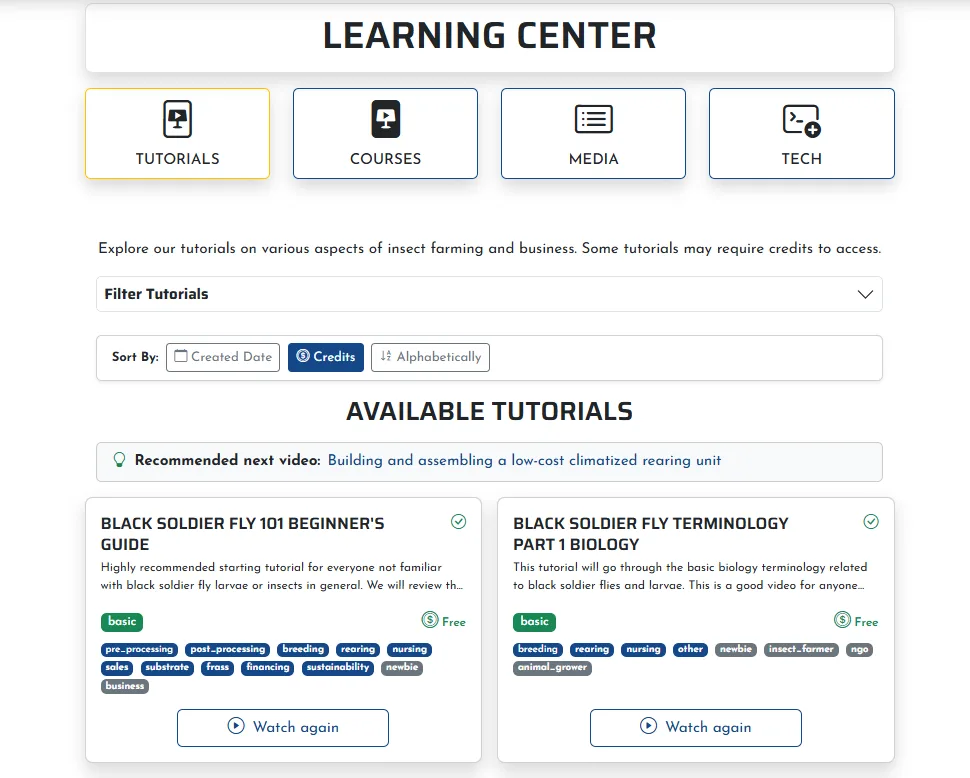

Manna Insect offers a comprehensive digital platform for anyone looking to learn, become a true professional in the insect industry, and build a profitable business.

You will learn everything you need from business strategies and farming processes to the affordable technologies that make efficient and successful local insect farms possible.