Build SCALABLE insect farming module locally

Manna Insect's proven and verified solutions provide the most cost-effective and risk-free opportunities for piloting and testing substrates and business models.

Build 100% effective BSF growing environment within weeks to get systematic results

Manna Insect has spent 7+ years developing cost-effective BSF farming modules. Now, we provide the expertise to help anyone start systematic and efficient BSF farming without climate risks.

These reference designs can be sourced and build locally by using available materials and equipment.

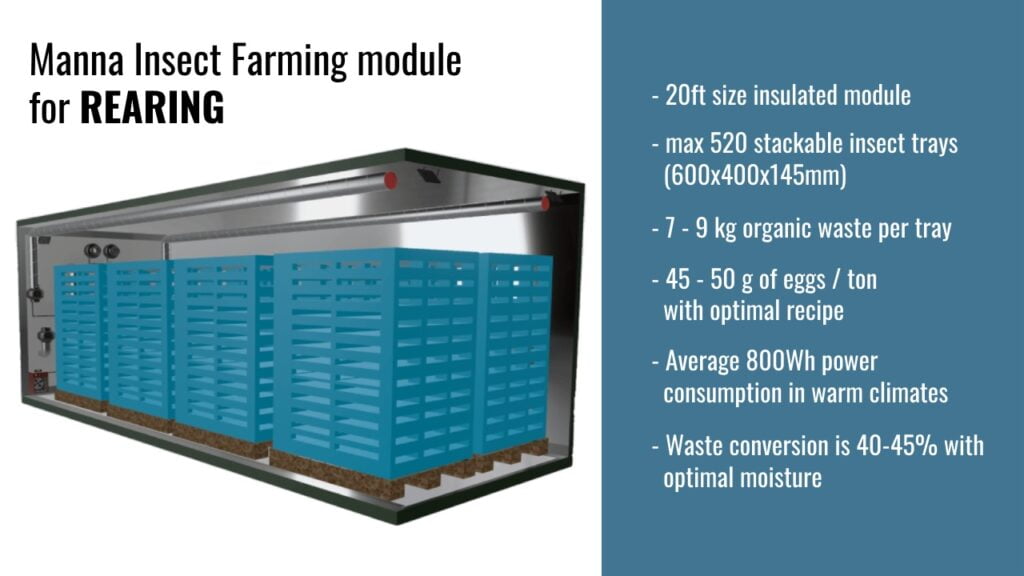

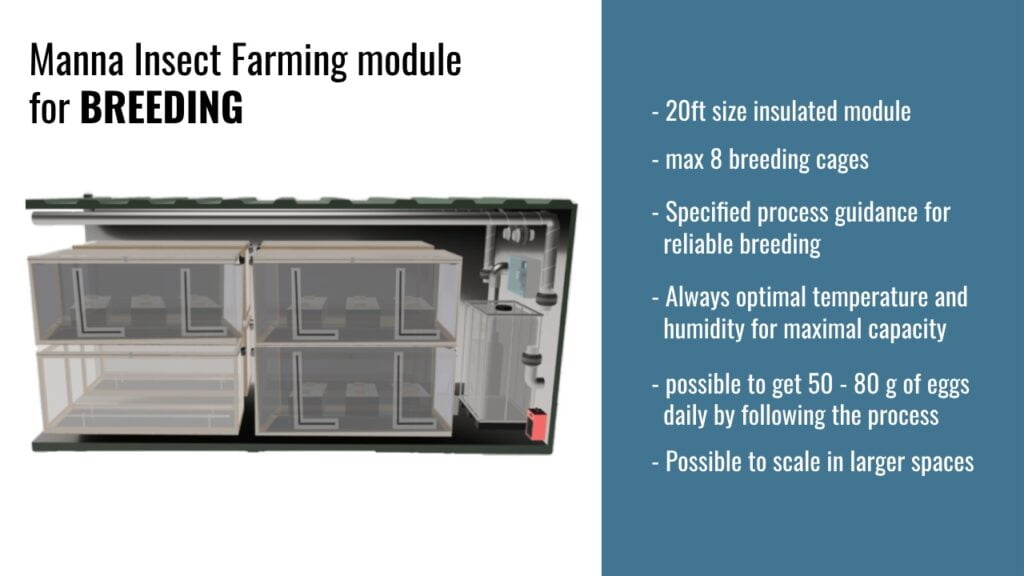

Reference designs

NOTE: Shipping container in the picture is just an example for the frame can be used and target numbers are according to this size.

Manna offer these as verified reference to accelerate process but MIND technology can be used with basically any size of spaces.

Example production capacity achievable in one rearing cycle with reference farming module and quality substrate

“Optimal climate and dedicated recipe will be converting all organic waste to clean larvae and dry frass, without leftovers from the waste”

Example of expenses of a pilot farming module

The price of a locally built insect farming module consists of the following components. More detailed list and budgeting tool can be found from Insect FARM hub

- Module & insulation

- Equipment

- Main A/C power unit

- Manna MIND hardware & software

- Insect trays for rearing

- Waste processing and separation

The total cost depends on the customer’s country, insulation requirements, and the availability of equipment and components.

You can create a budget for a locally built module within the Insect Farm Hub under Learning Center → Support.

What you need for the BSF production unit

Shopping list for BSF piloting and testing units

Proper insulation is essential for saving energy and reducing production costs, as it helps maintain optimal internal conditions with minimal energy use. It’s important to select insulation materials that correspond to the external temperature conditions, ensuring the system’s efficiency and cost-effectiveness.

The insulation material needs to be moisture-resistant, such as polyurethane, with all seams sealed and covered. Insulation is necessary in any weather conditions, and using high r-value materials will significantly reduce energy bills. PIR (Polyisocyanurate) or EPS (Expanded Polystyrene) sandwich panels are excellent options to consider for insulation.

Internal airflow is crucial to keeping larvae and flies active at all times. In our tested example installation, we use two long pipes with evenly spaced holes to distribute air uniformly throughout the space.

For ventilation, we use corrosion-resistant or plastic piping with 90-degree elbows to ensure durability and effective air circulation within the container. This setup helps maintain optimal conditions for the insects.

Pilot farming module should be equipped with paired semi-industrial inline duct fans for circulation, exhaust, and incoming air.

Example (Östberg CK160)

Larvae generate significant heat during digestion and movement, making it crucial to effectively lower the internal temperature to prevent overheating.

In compact-sized modules, it’s practical to use cost-effective, consumer-grade, low-power air conditioner split units for high-temperature regulation. These units offer an efficient and affordable solution to maintain the required climate conditions.

AC will be used only for cooling.

During the larvae rearing process, a significant amount of humidity is generated, and it’s essential to prevent water condensation by maintaining an optimal humidity level.

A single-phase semi-industrial dehumidifier (dryer) is highly effective in extracting moisture, ensuring the humidity remains at optimal levels. The recommended capacity for this setup is at least 50 liters per day. This helps to maintain a stable environment for larvae growth and prevent moisture-related issues.

Example (TTK 166 ECO)

Humidifier is essential especially for nursing and breeding spaces but it should be installed also in growing units because it will keep substrate moist enough when larvae are still small.

Small semi-industrial humidifiers can be sourced locally, but it is also possible to assemble one from individual parts using low-cost ultrasonic mist makers, which can be ordered from web shops.

Semi-industrial-grade fan heaters are essential for maintaining a consistent temperature throughout the rearing space. If at any point the temperature drops below 25°C, heating will be required during specific stages of the growth cycle to ensure optimal conditions for larvae development. These heaters help maintain a stable climate, preventing any negative impact on productivity.

Example (min 1 kW)

Basic lighting is essential for maintaining larvae within the trays throughout the entire growth cycle.

Special LED lights designed to mimic sunlight are available for breeding purposes, optimizing mating activities.

The main A/C power unit will be selected based on the size of the space and equipment are used. For example piloting modules we will provide an example list of components, schematics, and instructions for certified electricians to locally assemble the unit.

Example (by Manna Insect)

Rearing production

Stackable insect trays are essential to achieve maximum capacity

Example (600x400x145mm)

Breeding activities

locally build breeding cages, pupa boxes, egg traps and special LED light

- Example (Manna breeding cage design)

- Example (Manna pupa box and egg trap design

- Example (Breeding LED)

Nursing period

Nursing boxes with egg tables

Example (Manna nursing box design)

Separation

There is several possibilities to separate larvae from frass. For small and medium size production one vibrating sieve is enough.

Drying and defatting

There are several methods for drying the larvae, which vary depending on the time and cost ratio.

Manna Insect will provide detailed instructions and how-to guidelines

Other small tools such as weighing scales and crates are necessary for the production process.

One Manna MIND unit will manage a single farming space, whether for rearing, breeding, nursing, or a hybrid setup.

MIND technology consists of two main components:

- Hardware (HW): A set of physical modules that control farming equipment and collect real-time data.

- Software & Cloud Services: A locally installed control system that regulates the environment and transmits data to the cloud, allowing users to monitor conditions, analyze data, and adjust parameters remotely.

The MIND hardware package ranges from $600 to $950, depending on the chosen setup, and is available for direct purchase.

The annual subscription for the MIND software license and cloud services is $990 per unit.

Designs from the customers

Manna Insect serves customers in over 30 countries, most of whom have sourced and built their Black Soldier Fly farming units locally with support from the Insect Farm Hub platform and Manna.

Several customers have also customized the Manna Insect reference design to better suit their specific needs and local conditions.

Modular BSF farm in Brazil

Built fully locally including Manna MIND hardware

Capasity 3.5 – 4tn waste daily

Modal Box Content

BSF rearing unit in India

Built fully locally with Manna MIND GEN2 unit

Production capacity of 4tn daily in eight day cycle

Recipe testing unit in Europe

Built fully locally with

MIND GEN3 HW KIT

Automatic climate control and data collection

BSF mating room in England

Built fully locally with

MIND GEN2 UNIT

Capacity of 18 love cages with 54 cubic meter space

BSF rearing unit in Kenya

Built by local subcontractor with

MIND GEN2 UNIT

Processing capasity 3-4tn

R&D container in Spain

Built by Manna Insect for a Spanish university for R&D and trials

10ft size R&D container in Italy

Self-designed hybrid module for R&D purposed and trials

Capacity of doing full cycle

Rearing container in Australia

Locally sourced and build Manna reference container with MIND GEN2 unit

Addition to these few exampes Manna Insect have built or help to built black soldier fly farming module for example in USA, Columbia, Saudi-Arabia, New Zealand, Zambia, Germany, Sweden, Norway, Austria, Thailand amd Finland.